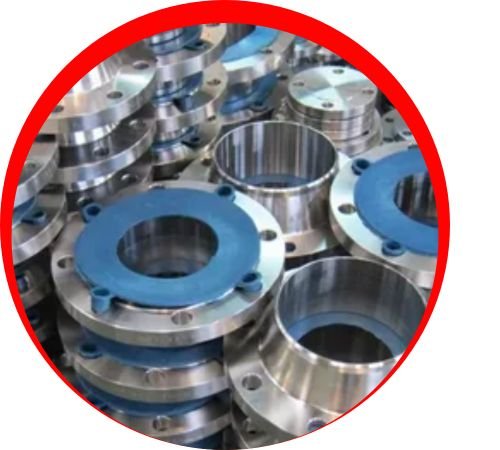

Nestled in the heart of Nigeria’s capital, Victor NickellAlloys stands as your trusted partner for industrial solutions. We specialize in providing high-performance Hastelloy Flanges, meticulously sourced to meet the rigorous demands of various sectors. Our commitment is to supply businesses in Abuja and across Nigeria with durable, reliable components that form the very backbone of safe and efficient operations, ensuring your projects are built to last with integrity and excellence.

These flanges are crafted from a unique nickel-chromium-molybdenum alloy, which gives them an exceptional ability to withstand harsh environments. Their key strength lies in resisting corrosion from aggressive chemicals, chlorides, and acidic media. This composition translates to outstanding mechanical properties, including high tensile strength and excellent thermal stability, ensuring they maintain structural integrity under extreme pressures and temperatures, project after project.

| Specifications | Hastelloy Flanges |

|---|---|

| ASME B16.5 Hastelloy C276 Flange size range | 1/2″ (15 NB) to 48″ (1200NB) DN10~DN5000 |

| Hastelloy Flanges Standards | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flanges. |

| Hastelloy C276 Flange Standard ANSI | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| Hastelloy C276 Flange Standard DIN | 6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64 |

| Hastelloy C276 Flange Standard JIS | 5K, 10 K, 16 K 20 K, 30 K, 40 K, 63 K |

| Hastelloy C276 Flange Standard UNI | 6Bar 10Bar 16Bar 25Bar 40Bar |

| Hastelloy C276 Flange Standard EN | 6Bar 10Bar 16Bar 25Bar 40Bar |

| Main Types | Forged / Threaded / Screwed / Plate |

| Flange supporting material | Gasket, Ring Joint, Flange Bolts |

| Hastelloy C276 Pipe Flanges Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Most common types of Hastelloy C276 Flanges |

|

| Production technique |

|

| Connect Type/ Flange Face Type | Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove |

| Special design | As per your drawing AS, ANSI, BS, DIN and JIS 15 NB (1/2″) to 200 NB (8″) Equal and Reducing Configurations Hastelloy C276 Threaded Flange, Socketweld Flange, Slip-On Flange, Blind Flange, Weld Neck Flange |

| Grade | Hastelloy C22 |

|---|---|

| C | 0.010 max |

| Mn | 0.50 max |

| Si | 0.08 max |

| S | 0.02 max |

| Co | 2.50 max |

| Ni | 50.015 min |

| Cr | 20.00 – 22.50 |

| Fe | 2.00 – 6.00 |

| Mo | 12.50 – 14.50 |

| P | 0.02 max |

| Density | 8.89 g/cm3 |

| Melting Point | 1370 °C (2500 °F) |

| Tensile Strength | Psi – 1,15,000 , MPa – 790 |

| Yield Strength (0.2%Offset) | Psi – 52000 , MPa – 355 |

| Elongation | 40 % |

At Victor Nickel Alloys, we take pride in being the largest supplier, exporter, and manufacturer of Hastelloy Flanges in Abuja, Nigeria, providing cutting-edge solutions for all your piping needs. Our state-of-the-art production plants are strategically located in the Nigeria, allowing us to maintain a vast inventory of over 16,000 tons of premium-quality materials readily available in stock. We are dedicated to delivering superior products and services, ensuring reliability and excellence for our global clientele.

Contact us to get a quick quote for your requirement.

You’ll typically find Hastelloy Flanges hard at work in some of the most demanding industrial settings. They are essential in chemical processing plants, where they handle corrosive acids and solvents, and in the oil and gas industry, managing the tough conditions of refining and offshore extraction. They also play a critical role in pollution control systems, pharmaceutical manufacturing, and other applications where failure is simply not an option, guaranteeing safety and operational continuity.