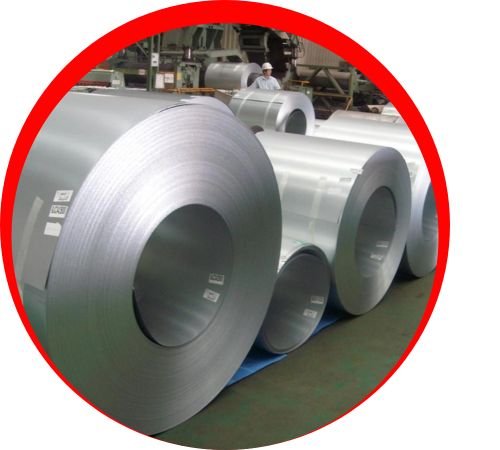

Victor Nickelalloys is a reliable manufacturer and supplier of Incoloy 800/800H/800HT Coils based in Abuja, Nigeria. They pride themselves on delivering top-notch products that are specifically designed to thrive in high-temperature and corrosive industrial settings. These coils are a go-to choice in petrochemical plants, power generation facilities, heat exchangers, and refineries, thanks to their outstanding resistance to oxidation and stress-related corrosion. At Victor Nickelalloys, the focus is on precision manufacturing, rigorous quality control, and compliance with global standards, ensuring that their products perform reliably in even the toughest applications. With a robust distribution network, deep technical know-how, and a commitment to customer service, they guarantee timely deliveries and consistent support for clients both in Nigeria and around the globe.

Incoloy 800/800H/800HT Coils are primarily made from nickel, iron, and chromium, with the addition of aluminum and titanium to boost their structural stability and resistance to carburization. Incoloy 800 provides solid high-temperature strength, while the 800H and 800HT variants offer enhanced creep and stress rupture resistance, thanks to their carefully controlled carbon content and specialized heat treatment processes. These coils showcase impressive tensile strength, thermal stability up to 1100°C, and exceptional resistance to oxidation, sulfidation, and chloride stress corrosion cracking. Their mechanical integrity makes them perfect for continuous exposure to high temperatures and chemically aggressive environments.

| Standard | ASTM B409 / ASME SB409 |

|---|---|

| Thickness | 0.2mm – 5.0mm |

| Width | 3.2mm – 1500mm |

| Length | AS PER CUSTOMER’S REQUIREMENT |

| Test Certificate | Yes |

| Coils Hardness | Half Hard, Quarter Hard, Soft, Hard, Spring Hard |

| Value Added Services | Cutting, Beveling, Polishing, Threading, Destructive, Non Destructive, Ultrasonic Testing |

| Form | Coil / Strip |

| Make | Jindal, Bahru, Posco Korea, Posco Thainox, Columbus, Acerinox, Aperam, Tisco, Nisshin, Nippon And Many More Mills. |

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr | Al | Ti |

| Alloy 800 | 0.10 max | 1.50 max | 1.00 max | 0.015 max | 0.75 max | 39.50 min | 30.00 – 35.00 | 19.00 – 23.00 | 0.15 – 0.60 | 0.15 – 0.60 |

| Alloy 800H | 0.05 – 0.10 | 1.50 max | 1.00 max | 0.015 max | 0.75 max | 39.50 min | 30.00 – 35.00 | 19.00 – 23.00 | 0.15 – 0.60 | 0.15 – 0.60 |

| Alloy 800HT | 0.06 – 0.10 | 1.50 max | 1.00 max | 0.015 max | 0.75 max | 39.50 min | 30.00 – 35.00 | 19.00 – 23.00 | 0.15 – 0.60 | 0.15 – 0.60 |

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Incoloy 800 / 800H / 800HT | 7.94 g/cm3 | 1385 °C (2525 °F) | Psi – 75,000 , MPa – 520 | Psi – 30,000 , MPa – 205 | 30 % |

At Victor Nickel Alloys, we take pride in being the largest supplier, exporter, and manufacturer of Incoloy 800/800H/800HT Coils in Abuja, Nigeria, providing cutting-edge solutions for all your piping needs. Our state-of-the-art production plants are strategically located in the Nigeria, allowing us to maintain a vast inventory of over 16,000 tons of premium-quality materials readily available in stock. We are dedicated to delivering superior products and services, ensuring reliability and excellence for our global clientele.

Incoloy 800/800H/800HT Coils find extensive use in industries where materials need to endure extreme heat, corrosive conditions, and mechanical stress. They’re commonly found in heat exchangers, furnace components, steam superheaters, gas turbine systems, petrochemical processing units, and boiler equipment. In the oil and gas sector, these coils are essential in reactors, cracking units, and high-temperature piping systems. Their thermal stability makes them ideal for industrial heating systems, power plants, chemical processing facilities, and refineries.