Welcome to Victor Nickelalloys, your trusted partner for high-performance materials right here in Abuja. We specialize in supplying and manufacturing Inconel 600 Bars, providing local industries with direct access to top-tier nickel-chromium alloys. Our commitment is to support Nigeria’s growing engineering and industrial sectors with reliable, readily available stock that meets the most demanding specifications, ensuring your projects proceed without delay.

Inconel 600 is a nickel-chromium alloy known for its exceptional strength and resistance. It maintains its integrity in high temperatures and resists oxidation, thanks to its composition which is primarily nickel, with significant chromium and iron content. This combination gives the bars excellent mechanical properties, including good tensile strength and outstanding resistance to corrosion and stress-corrosion cracking, making them incredibly durable in tough conditions.

| Specification | ASTM B166 UNS N06600, AMS 5665 |

|---|---|

| Flat bar size | Thickness: 2 -100mm |

| Width: 10 to 500mm | |

| Square bar size | 4 to 100mm |

| Round bar size | Diameter: 3-~800mm |

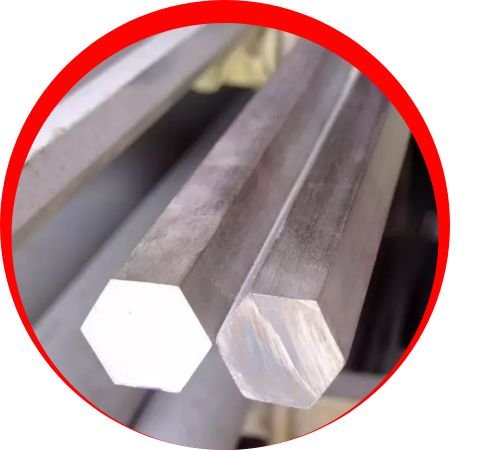

| Hex Bar size | 2-100mm A/F |

| Channel Bar | 80 x 40mm to 150 x 75mm section; 5.0 to 6.0mm thickness |

| Hollow Bar | 32mm OD x 16mm ID to 250mm OD x 200mm ID) |

| Angle bar size | 3mm*20mm*20mm~12mm*100mm*100mm |

| Section | 3.0 to 12.0mm thickness |

| Rectangles Size | 33 x 30mm to 295 x 1066mm |

| Billet Size | 1/2″ to 495mm Diameter |

| Finish | Cold (bright) drawn, centreless ground, hot rolled, smooth turned, peeled, slit rolled edge, hot rolled annealed, Rough Turned, Bright, Polish, Grinding, Centreless Ground & Black |

| Condition | Hardened & tempered, annealed |

| Technique | 600 Inconel Cold Drawn, Hot Rolled, Forged Round Bar, Rod, Cold Rolled |

| Tolerance | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients’ requirements |

| Surface | Cold Drawn, Bright, Sand Blasting Finished, Hot Rolled Pickled, Hairline, Polished |

| Processing | Bar cutting to 650mm |

| Form | Precision Ground Bar, Flat Bar, Square, Round, Half Round Bar, Rod, Rectangle, Hex (A/F), T-Bar, Channel Bar, Blocks, Round Rod, Threaded, Profiles, Billet, Ingot, I/H Bar, Forging, Rings, Hollow, Triangle etc. |

| Grade | Ni | Cr | Fe | C | Mn | S | Si | Cu |

|---|---|---|---|---|---|---|---|---|

| Inconel 600 | 72.0 min | 14.0 – 17.0 | 6.0 – 10.0 | 0.15 max | 1.0 max | 0.015 max | 0.5 max | 0.5 max |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|

| 8.47 g/cm3 | 1413 °C (2580 °F) | Psi – 95,000 , MPa – 655 | Psi – 45,000 , MPa – 310 | 40 % |

At Victor Nickel Alloys, we take pride in being the largest supplier, exporter, and manufacturer of Inconel 600 Bars in Abuja, Nigeria, providing cutting-edge solutions for all your piping needs. Our state-of-the-art production plants are strategically located in the Nigeria, allowing us to maintain a vast inventory of over 16,000 tons of premium-quality materials readily available in stock. We are dedicated to delivering superior products and services, ensuring reliability and excellence for our global clientele.

Contact us to get a quick quote for your requirement.

The versatility of Inconel 600 Bars makes them indispensable across numerous fields. They are commonly used in the aerospace industry for turbine components, in heat treatment fixtures for their temperature resistance, and in chemical processing plants where equipment must withstand corrosive environments. You’ll also find them in power generation systems, nuclear reactors, and even in everyday applications like furnace systems, proving their value wherever heat and corrosion are constant challenges.