Welcome to Victor Nickelalloys, your trusted partner in Abuja for premium-grade Inconel 625 bars. We pride ourselves on being more than just a supplier; we are dedicated specialists committed to providing robust and reliable materials that meet the demanding needs of Nigeria’s key industries. Our focus is on delivering exceptional quality and local support, ensuring your projects are built on a foundation of superior performance and durability, right here in the heart of the nation.

The strength of Inconel 625 comes from its unique composition, primarily a blend of nickel and chromium, fortified with significant amounts of niobium and molybdenum. This specific recipe gives the bars outstanding mechanical properties, including remarkable tensile strength and excellent fatigue resistance. They maintain their integrity under extreme stress and high temperatures, offering superb creep resistance, which makes them a go-to material for challenging environments where other metals would fail.

| Specifications | : | ASTM B446 / ASTM SB446 |

| Dimensions | : | EN, DIN, JIS, ASTM, BS, ASME, AISI |

| Size | : | 5 mm To 500 mm |

| Diameter | : | 0.1 mm to 100 mm |

| Length | : | 100 mm To 3000 mm Long & Above |

| Finish | : | Black, Bright Polished, Rough Turned, NO.4 Finish, Matt Finish, BA Finish |

| Tolerance | : | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients’ requirements |

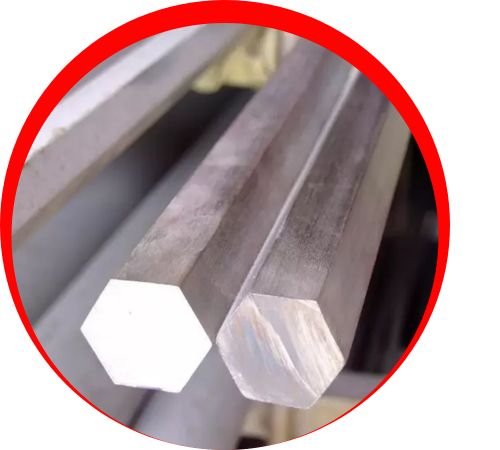

| Form | : | Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forging Etc. |

| Grade | C | Mn | Si | Cu | S | Fe | Mo | Ni | Cr |

| Inconel 625 | 0.10 max | 0.50 max | 0.50 max | – | 0.15 min | 5.0 max | – | 58.0 min | 20.0–23.0 |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.4 g/cm3 | 1.350 °C (2460 °F) | Psi – 1,35,000 , MPa – 930 | Psi – 75,000 , MPa – 517 | 42.5 % |

At Victor Nickel Alloys, we take pride in being the largest supplier, exporter, and manufacturer of Inconel 625 Bars in Abuja, Nigeria, providing cutting-edge solutions for all your piping needs. Our state-of-the-art production plants are strategically located in the Nigeria, allowing us to maintain a vast inventory of over 16,000 tons of premium-quality materials readily available in stock. We are dedicated to delivering superior products and services, ensuring reliability and excellence for our global clientele.

Contact us to get a quick quote for your requirement.

Because of its exceptional resilience, Inconel 625 bars are indispensable across several critical sectors. They are widely used in the oil and gas industry for components like downhole well equipment and valve trim, where resistance to sour gas is essential. The aerospace and chemical processing industries also rely heavily on these bars for turbine blades, exhaust systems, and reactor modules, leveraging their ability to withstand intense heat and corrosive substances, ensuring long-term safety and operational efficiency.