Victor Nickelalloys stands out as a trusted manufacturer and supplier of Inconel 800 Bars in Abuja, Nigeria. They specialize in high-performance nickel-iron-chromium alloy products that are built for remarkable strength and resistance to corrosion. Inconel 800 (UNS N08800) is a go-to choice for high-temperature applications, thanks to its stability, oxidation resistance, and ability to maintain its mechanical properties even under prolonged heat exposure. These bars are perfect for use in heat exchangers, furnace components, petrochemical processing, and power generation systems. Victor Nickelalloys guarantees precision-engineered Inconel 800 Bars that adhere to international standards for toughness, durability, and dimensional accuracy, ensuring reliable performance in harsh chemical and thermal environments.

Inconel 800 Bars are made up of roughly 30–35% nickel, 19–23% chromium, and 39.5% iron, with small amounts of carbon, aluminum, and titanium added to boost strength and stability. This alloy boasts a tensile strength of about 550 MPa, a yield strength of around 240 MPa, and an elongation of 30%. It excels in oxidation and carburization resistance up to 1100°C. Inconel 800 also offers excellent stress rupture and creep resistance, ensuring consistent mechanical performance even under thermal cycling, high-pressure conditions, and corrosive environments that involve acids, salts, and combustion gases.

| Standards : | ASTM B408, ASME SB408 |

| Dimensions : | EN, DIN, JIS, ASTM, BS, ASME, AISI |

| Wire : | Thickness starting from 0.05mm |

| Round bar size : | Diameter: 3-~800mm |

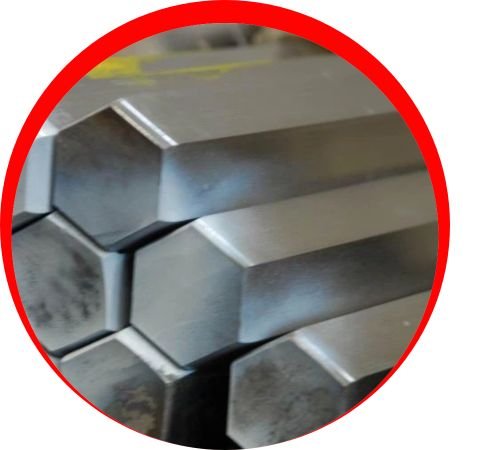

| Hex Bar size : | 2-100mm A/F |

| Flat bar size : | Thickness: 2 -100mm / Width: 10 to 500mm |

| Square bar size : | 4 to 100mm |

| Rectangular Bars Size : | 33 x 30mm to 295 x 1066mm |

| Hollow Bar : | 32mm OD x 16mm ID to 250mm OD x 200mm ID |

| Tolerance : | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients’ requirements |

| Finish : | Black, Bright Polished, Rough Turned, NO.4 Finish, Matt Finish, BA Finish |

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr | Al | Ti |

| Inconel 800 | 0.10 max | 1.50 max | 1.00 max | 0.015 max | 0.75 max | 39.50 min | 30.00 – 35.00 | 19.00 – 23.00 | 0.15 – 0.60 | 0.15 – 0.60 |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 7.94 g/cm3 | 1385 °C (2525 °F) | Psi – 75,000 , MPa – 520 | Psi – 30,000 , MPa – 205 | 30 % |

At Victor Nickel Alloys, we take pride in being the largest supplier, exporter, and manufacturer of Inconel 800 Bar in Abuja, Nigeria, providing cutting-edge solutions for all your piping needs. Our state-of-the-art production plants are strategically located in the Nigeria, allowing us to maintain a vast inventory of over 16,000 tons of premium-quality materials readily available in stock. We are dedicated to delivering superior products and services, ensuring reliability and excellence for our global clientele.

Contact us to get a quick quote for your requirement.

Inconel 800 Bars find extensive use in heat-treating equipment, furnace components, chemical processing, and power generation systems where high-temperature strength and oxidation resistance are crucial. They are particularly suited for superheater and reheater tubes, heat exchangers, pressure vessels, and cracking furnaces in the petrochemical industry. In nuclear power plants, these bars are utilized in steam generators and reactor core components due to their dimensional stability under radiation and stress. Additionally, they are applied in industrial heaters, condensers, and offshore applications, showcasing their versatility and reliability in demanding environments.