Victor Nickel Alloys is a leading manufacturer and supplier based in Abuja, Nigeria, specializing in high performance alloys and materials. With a strong reputation for quality and reliability, they offer a wide range of products including the Inconel 800-H Bar. Known for its excellent resistance to oxidation and high environmental temperatures, Inconel 800-H is widely used in aerospace, chemical, power generation and other industries Victor Nickel Alloys ensures that materials high quality and customer satisfaction, making them a reliable partner in the industry.

Victor NickelAlloys, based in Abuja, Nigeria, stands out as a top-notch manufacturer and supplier of high-quality Inconel 800-H bars. Known for their precision engineering and unwavering commitment to excellence, they cater to a variety of industries, including chemical processing, power generation, petrochemical, and aerospace. By employing cutting-edge manufacturing techniques and strict quality control measures, Victor NickelAlloys guarantees that each Inconel 800-H bar adheres to international standards. Their ability to produce custom lengths, diameters, and finishes, combined with prompt delivery, makes them a reliable partner for businesses in need of durable, corrosion-resistant, and heat-resistant bars for challenging applications both in Nigeria and beyond.

| Standards : | ASTM B408, ASME SB408 |

| Dimensions : | EN, DIN, JIS, ASTM, BS, ASME, AISI |

| Wire : | Thickness starting from 0.05mm |

| Round bar size : | Diameter: 3-~800mm |

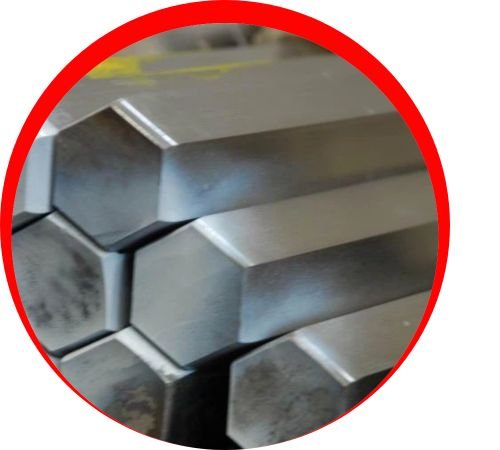

| Hex Bar size : | 2-100mm A/F |

| Flat bar size : | Thickness: 2 -100mm / Width: 10 to 500mm |

| Square bar size : | 4 to 100mm |

| Rectangular Bars Size : | 33 x 30mm to 295 x 1066mm |

| Hollow Bar : | 32mm OD x 16mm ID to 250mm OD x 200mm ID |

| Tolerance : | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients’ requirements |

| Finish : | Black, Bright Polished, Rough Turned, NO.4 Finish, Matt Finish, BA Finish |

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr | Al | Ti |

| 800H | 0.05 – 0.10 | 1.50 max | 1.00 max | 0.015 max | 0.75 max | 39.50 min | 30.00 – 35.00 | 19.00 – 23.00 | 0.15 – 0.60 | 0.15 – 0.60 |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 7.94 g/cm3 | 1385 °C (2525 °F) | Psi – 75,000 , MPa – 520 | Psi – 30,000 , MPa – 205 | 30 % |

The Inconel 800-H bars crafted by Victor NickelAlloys primarily consist of nickel (30–35%), chromium (19–23%), and iron (the balance), with small amounts of copper and titanium added. This unique composition offers outstanding resistance to oxidation, corrosion, and high-temperature conditions. On the mechanical side, Inconel 800-H bars showcase impressive tensile strength, excellent creep resistance, and remarkable stability at elevated temperatures. The material retains its structural integrity even under thermal cycling, making it perfect for industrial applications that demand durability in extreme environments. Each bar undergoes meticulous testing for hardness, yield strength, and elongation to ensure dependable and consistent performance.

Contact us to get a quick quote for your requirement.

Inconel 800-H bars from Victor NickelAlloys find extensive use in industries that require exceptional heat and corrosion resistance. Common applications include furnace components, heat exchangers, chemical reactors, nuclear equipment, and high-temperature piping systems. Its remarkable mechanical properties make it ideal for power plants, petrochemical facilities, and aerospace applications where performance in harsh conditions is essential. By delivering durable and reliable solutions, Victor NickelAlloys continues to support industries that rely on high-quality materials.