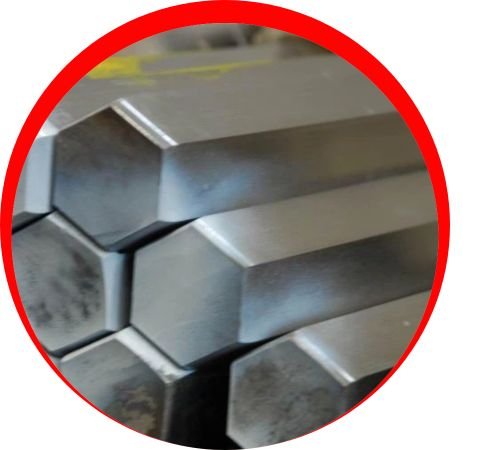

Victor Nickelalloys stands out as a reliable manufacturer and supplier of Inconel 925 and 926 Bars in Abuja, Nigeria. They offer top-notch nickel-based alloys that are crafted for exceptional strength and resistance to corrosion, even in the toughest environments. Inconel 925 and 926 are precipitation-hardenable alloys that blend nickel, chromium, and molybdenum, with a touch of titanium and aluminum to enhance their mechanical properties. These bars excel in resisting stress cracking, pitting, and oxidation, making them perfect for acidic, marine, and chemical applications. Victor Nickelalloys delivers precision-engineered Inconel 925/926 Bars tailored for the oil and gas, marine, petrochemical, and power generation sectors, ensuring they perform reliably under extreme conditions.

Inconel 925 Bars are primarily made up of nickel (42–46%), iron (22–30%), chromium (19.5–23.5%), molybdenum (2.5–3.5%), and copper (1.5–3%). On the other hand, Inconel 926 Bars feature nickel (24–26%), chromium (19–21%), molybdenum (6–7%), along with nitrogen and copper to boost corrosion resistance. Both alloys showcase impressive tensile strength ranging from 850 to 1000 MPa, yield strength between 500 and 650 MPa, and elongation of 25 to 35%. They are known for their remarkable resistance to pitting, crevice corrosion, and chloride stress cracking, along with excellent toughness, weldability, and oxidation resistance across a wide range of temperatures.

| Specification : | ASTM B805 / ASME SB805 |

| Size : | 14mm-300mm |

| Diameter : | 0.1 mm to 100 mm |

| Thickness : | 50 mm to 6000 mm Long |

| Length : | 1 To 6 Meters, Custom Cut Length |

| Finish : | Bright, Polish & Black |

| Grade | C | Mo | Si | S | Cu | Fe | Ni | Cr | Al | Ti |

| Incoloy 925 | 0.01 max | 3 max | 0.5 max | 0.03 max | 1.8 | 28 | 44 | 21 | 0.3 | 2.1 |

| Incoloy 926 | ≤0.02 | 6-7 | ≤0.5 | ≤0.01 | 0.5-1.5 | 41.69 – 50.35 | 24-26 | 19-21 | – | – |

| Yield strength RP0.2, MPA | Tensile strength RM, MPA | Elongation [%] | Hardness [HRC] | Impact, Charpy-V, -60ºC [J] |

| ≥ 758 | ≥ 965 | ≥ 25 | ≤ 38 | ≥ 47 |

| ≥296 MPa – ≥43000 psi | ≥648 MPa – ≥94000 psi | ≥35 % | – | ≥ 47 |

At Victor Nickel Alloys, we take pride in being the largest supplier, exporter, and manufacturer of Inconel 925 and 926 Bar in Abuja, Nigeria, providing cutting-edge solutions for all your piping needs. Our state-of-the-art production plants are strategically located in the Nigeria, allowing us to maintain a vast inventory of over 16,000 tons of premium-quality materials readily available in stock. We are dedicated to delivering superior products and services, ensuring reliability and excellence for our global clientele.

Contact us to get a quick quote for your requirement.

Inconel 925/926 Bars find extensive applications in offshore oil and gas drilling, marine engineering, chemical processing, and desalination plants, thanks to their exceptional corrosion and stress resistance. Inconel 925 is often the go-to choice for downhole tubing, valves, hangers, and fasteners that face sour gas and high-pressure conditions, while Inconel 926 is perfect for heat exchangers, pressure vessels, flue-gas scrubbers, and equipment in chemical plants. These alloys maintain outstanding performance in environments rich in chloride, acidic conditions, and seawater, making them ideal for refineries and power generation facilities.