Victor Nickelalloys stands out as a top-notch manufacturer and supplier located in Abuja, Nigeria, with a focus on producing high-quality Inconel X-750 bars. These bars are celebrated for their remarkable strength, resistance to corrosion, and ability to perform under high temperatures, making them perfect for tough industrial settings. Catering to industries like aerospace, power generation, chemical processing, and oil and gas, Victor Nickelalloys guarantees that every Inconel X-750 bar adheres to international quality standards. With a commitment to precision, durability, and prompt delivery, their products offer dependable solutions for critical structural and high-stress applications throughout Nigeria and beyond.

The composition of Inconel X-750 bars includes nickel, chromium, and iron, along with titanium and aluminum, which contribute to their outstanding mechanical strength and resistance to corrosion and oxidation at high temperatures. These bars are designed to maintain stability even under extreme heat and stress, making them ideal for applications that demand long-lasting durability and high fatigue resistance. Victor Nickelalloys produces these bars in a variety of sizes and specifications to cater to the diverse needs of various industrial applications.

| Standards : | ASTM B637, ASME SB637 |

| Dimensions : | EN, DIN, JIS, ASTM, BS, ASME, AISI |

| Wire : | Thickness starting from 0.05mm |

| Round bar size : | Diameter: 3-~800mm |

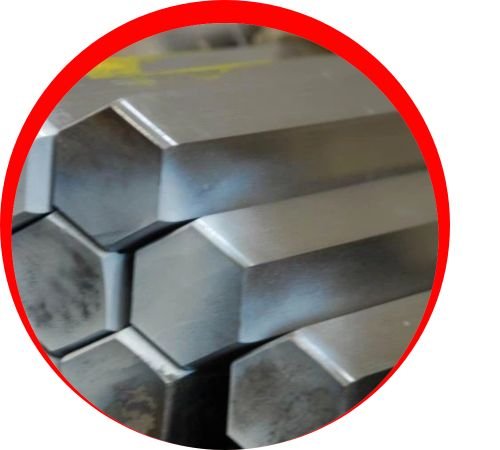

| Hex Bar size : | 2-100mm A/F |

| Flat bar size : | Thickness: 2 -100mm / Width: 10 to 500mm |

| Square bar size : | 4 to 100mm |

| Rectangular Bars Size : | 33 x 30mm to 295 x 1066mm |

| Hollow Bar : | 32mm OD x 16mm ID to 250mm OD x 200mm ID |

| Tolerance : | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients’ requirements |

| Finish : | Black, Bright Polished, Rough Turned, NO.4 Finish, Matt Finish, BA Finish |

| Grade | C | Mn | Si | S | Cu | Ni | Cr | Ai | Ti |

| Inconel X-750 | .08 max | 1.00 max | 0.50 max | 0.01 max | 0.50 max | 70.0 min | 14.0 – 17.0 | 0.40 – 1.0 | 2.25 – 2.75 |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.28 g/cm3 | 1430°C | 1267 MPa | 868 MPa | 25 % |

Inconel X-750 bars from Victor Nickelalloys find extensive use in turbine components, aerospace fasteners, heat exchangers, nuclear reactors, and chemical processing equipment. They excel in environments that experience high temperatures, corrosive conditions, and cyclic loading. With their unique blend of strength, corrosion resistance, and thermal stability, these bars ensure reliable performance, making them a preferred choice for industrial, aerospace, and energy applications both in Nigeria and on the international stage.

Contact us to get a quick quote for your requirement.

Inconel X-750 bars are widely used in applications that require excellent mechanical strength and high temperature and corrosion resistance. Because of their ability to withstand high temperatures and provide stability, they are widely used in gas turbines, rocket engines, and nuclear power plants These rods are also used in springs, fasteners and bolts for systems highly efficient in aerospace and pharmaceutical applications. Their high oxidation resistance makes them ideal for heating appliances and industrial furnaces, providing long life under extreme conditions.