Home > Super Duplex Steel > Super Duplex Steel Flanges S32750

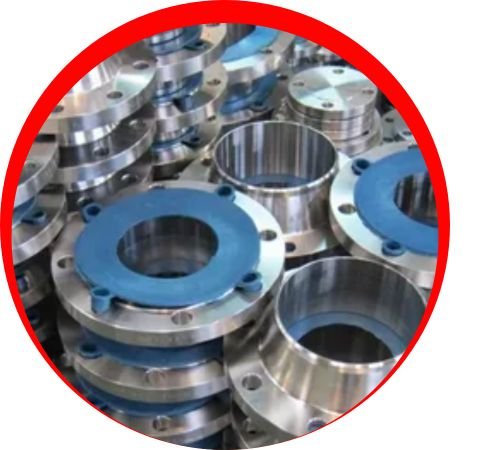

Victor Nickel Alloys stands out as a top-notch manufacturer and supplier of **Super Duplex Steel Flanges S32750**, proudly based in Abuja, Nigeria. The company has built a solid reputation for crafting high-quality duplex and super duplex products that meet international standards for both performance and durability. Thanks to their modern production methods and rigorous quality checks, Victor Nickel Alloys guarantees that their flanges offer remarkable strength, toughness, and resistance to corrosion. Industries like oil and gas, petrochemical, power generation, and marine engineering rely on their **Super Duplex Steel Flanges S32750** for dependable performance, even in the toughest conditions. Victor Nickel Alloys is a leading manufacturer and supplier of Super Duplex Steel Flanges S32750 in Abuja, Nigeria. Our S32750 flanges are crafted to provide exceptional strength and superior corrosion resistance for demanding industrial applications. With high chromium and molybdenum content, these flanges offer excellent protection against stress corrosion cracking, pitting, and erosion. They are ideal for use in offshore oil and gas platforms, chemical processing, and marine environments, ensuring reliable performance and durability under extreme conditions. At Victor Nickel Alloys, we are committed to delivering top-quality Super Duplex Steel Flanges S32750 that meet the highest industry standards. Rely on us for robust and high-performance solutions tailored to your specific needs.

These **Super Duplex Steel Flanges S32750** are made up of **25% chromium, 7% nickel, and 4% molybdenum**, along with trace amounts of **nitrogen, tungsten, and copper**. This carefully balanced austenitic-ferritic microstructure provides outstanding resistance to **pitting, crevice corrosion, and chloride-induced stress corrosion cracking**. With a **tensile strength of around 800 MPa**, a **yield strength of 550 MPa**, and an **elongation of about 25%**, they deliver excellent mechanical performance and toughness, even in high-stress and high-temperature situations.

| Specifications | ASTM A182 / ASME SA182 |

| Size | 1/8″ NB TO 48″ NB |

| Standards | ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Class / Pressure | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Standard | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. |

| Grades | S31803 / S32205 A182 Gr F51 / F52 / F53 / F54 / F55 / F57 / F59 / F60 / F61 |

| Grade | Duplex Steel Flanges |

|---|---|

| C | 0.030 max |

| Mn | 2.00 max |

| Si | 1.00 max |

| P | 0.030 max |

| S | 0.020 max |

| Cr | 22.0 – 23.0 |

| Mo | 3.0 – 3.5 |

| Ni | 4.50 – 6.50 |

| N | 0.14 – 0.20 |

| Fe | 63.72 min |

| Duplex Steel | Flanges |

|---|---|

| Density (g/cm 3) | 7.805 |

| Density (lb/in 3) | 0.285 |

| Melting Point (°C) | 1420 – 1465 |

| Melting Point (°F) | 2588 – 2669 |

At Victor Nickel Alloys, we take pride in being the largest supplier, exporter, and manufacturer of Super Duplex Steel S32750 Flanges in Abuja, Nigeria, providing cutting-edge solutions for all your piping needs. Our state-of-the-art production plants are strategically located in the Nigeria, allowing us to maintain a vast inventory of over 16,000 tons of premium-quality materials readily available in stock. We are dedicated to delivering superior products and services, ensuring reliability and excellence for our global clientele.

Contact us to get a quick quote for your requirement.

You’ll find **Super Duplex Steel Flanges S32750** commonly used in **offshore oil and gas platforms**, **chemical and petrochemical processing plants**, and **marine environments**, thanks to their remarkable resistance to seawater and corrosive fluids. They’re also perfect for **heat exchangers, pressure vessels, desalination plants**, and the **pulp and paper industries**, where strength and durability are crucial. Plus, these flanges are ideal for **power generation systems** and **pipeline connections** in harsh settings, ensuring secure and long-lasting joints that hold up under high pressure and mechanical stress.