Victor Nickel Alloys is a reputable manufacturer and supplier of Titanium Bars located in Abuja, Nigeria. The company has built a solid reputation for crafting high-quality titanium products that adhere to international standards for strength, durability, and resistance to corrosion. With state-of-the-art manufacturing facilities and robust quality control systems, Victor Nickel Alloys provides precision-engineered titanium bars that are perfect for demanding industrial applications. They cater to a diverse array of industries, including aerospace, marine, oil and gas, chemical processing, and medical sectors, delivering products that ensure exceptional performance and long-lasting reliability even in tough environments.

Titanium Bars are mainly made from commercially pure titanium or titanium alloys like Grade 2 and Grade 5 (Ti-6Al-4V). These materials are known for their impressive corrosion resistance, high strength-to-weight ratio, and remarkable heat resistance. With tensile strengths reaching up to 950 MPa and a melting point around 1660°C, titanium bars also exhibit excellent fatigue resistance. They retain their mechanical properties even in extreme conditions, making them ideal for high-performance and corrosive environments where strength, stability, and longevity are crucial.

| Specifications | : | ASTM B348/ ASTM SB348 |

| Dimensions | : | EN, DIN, JIS, ASTM, BS, ASME, AISI |

| Size | : | 5 mm To 500 mm |

| Diameter | : | 0.1 mm to 100 mm |

| Length | : | 100 mm To 3000 mm Long & Above |

| Finish | : | Black, Bright Polished, Rough Turned, NO.4 Finish, Matt Finish, BA Finish |

| Tolerance | : | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients’ requirements |

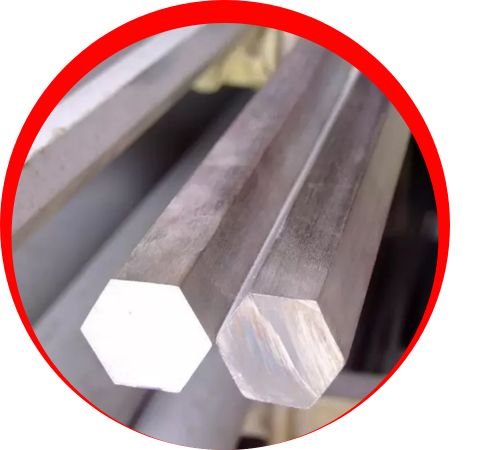

| Form | : | Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forging Etc. |

At Victor Nickel Alloys, we take pride in being the largest supplier, exporter, and manufacturer of Titanium Bars in Abuja, Nigeria, providing cutting-edge solutions for all your piping needs. Our state-of-the-art production plants are strategically located in the Nigeria, allowing us to maintain a vast inventory of over 16,000 tons of premium-quality materials readily available in stock. We are dedicated to delivering superior products and services, ensuring reliability and excellence for our global clientele.

Contact us to get a quick quote for your requirement.

Titanium Bars find extensive use in industries that prioritize strength, lightweight design, and corrosion resistance. In aerospace engineering, they are vital for aircraft components, engine parts, and structural frameworks. In marine and offshore sectors, titanium bars stand up to seawater corrosion, making them perfect for shipbuilding and underwater applications. They are also utilized in chemical processing equipment, oil and gas systems, medical implants, and automotive components. Thanks to their biocompatibility, they are particularly well-suited for surgical instruments and prosthetics, ensuring durability, safety, and reliability in both industrial and biomedical settings.