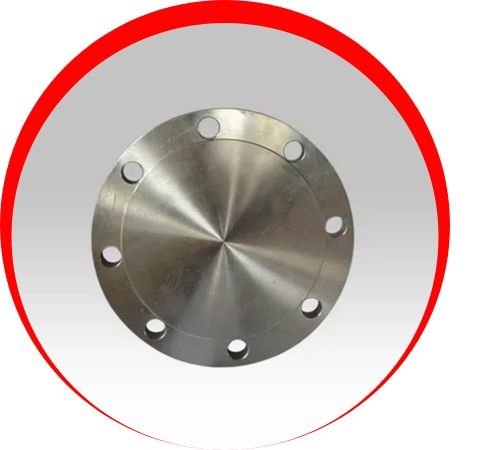

Victor Nickelalloys, a top-notch manufacturer and supplier located in Abuja, Nigeria, specializes in high-quality Titanium Flanges that are built to resist corrosion, provide strength, and ensure durability. Crafted from premium-grade titanium through advanced forging and machining methods, these flanges are perfect for tough environments where both strength-to-weight ratio and corrosion resistance are essential. Industries like chemical processing, marine, aerospace, and power generation widely rely on Titanium Flanges from Victor Nickelalloys. Each flange is meticulously engineered to meet international standards, guaranteeing outstanding performance, precise dimensions, and a long lifespan even in high-pressure and high-temperature situations.

These Titanium Flanges mainly consist of commercially pure titanium (Grades 2 and 5), striking a great balance between strength and corrosion resistance. They have a melting point of 1660°C and a density of 4.51 g/cm³, making them lightweight yet incredibly durable. With tensile strength ranging from 345 MPa (Grade 2) to 895 MPa (Grade 5), these flanges can handle extreme mechanical stress while still being easy to form and weld. Titanium’s remarkable resistance to both oxidizing and reducing agents, combined with its low thermal expansion and high fatigue resistance, makes these flanges ideal for demanding industrial settings.

| Specifications | : | ASTM B381 / ASME SB381 |

| Size | : | 1/2″NB TO 60″NB |

| Standards | : | ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Class / Pressure | : | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Standard | : | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. |

At Victor Nickel Alloys, we take pride in being the largest supplier, exporter, and manufacturer of Titanium Flanges in Abuja, Nigeria, providing cutting-edge solutions for all your piping needs. Our state-of-the-art production plants are strategically located in the Nigeria, allowing us to maintain a vast inventory of over 16,000 tons of premium-quality materials readily available in stock. We are dedicated to delivering superior products and services, ensuring reliability and excellence for our global clientele.

Contact us to get a quick quote for your requirement.

Victor Nickelalloys’ Titanium Flanges are extensively utilized in the chemical and petrochemical sectors for piping systems, heat exchangers, and reactors that deal with corrosive materials. In the marine industry, they are essential for shipbuilding, offshore drilling, and desalination systems due to their ability to withstand seawater corrosion. The aerospace sector incorporates them into aircraft engines, hydraulic systems, and exhaust structures, while the medical field uses them in surgical devices and biocompatible equipment. Furthermore, these flanges find applications in power generation and automotive industries where lightweight strength and durability are crucial.